Cyclone and wine cabinet progress

Here is the filter stack with the new pedestal box that I built. The box is screwed to the botom of the filters and the transition piece at the top is also screwed to the top of the filters.

It is held closed with a window sash lock and has weather stripping to keep it air tight. Inside is a removeable drawer for the really fine dust.

All that is left is screwing the duct pieces together and caulking all the joints.

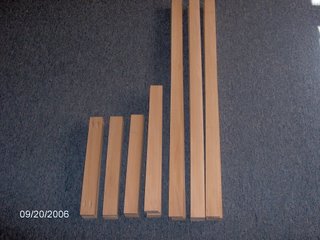

As for the wine cabinet, the following picture is the result of 6 hours of work.

From left to right the stacks represent the panels that go into the frames, the back side frame pieces, the bottom filler pieces, and the back filler pieces. All of this starts out as full 1 inch rough sawn lumber, 8 feet long, which includes ragged ends, knots, and various other defects. The time includes measuring and marking around the defects, rough cutting oversize, trimming one edge clean, then trimming the other edge parallel to the first. Lots of planing and jointing to come. If this cabinet were to be painted then buying plywood would have been the way to go.

Currently trying to design a sled to run through the surface planer to true up one face of the pictured boards (the second face is no problem). The sled should be 48" long, hold the piece firmly, and be quick to set up since there are so many pieces. I have a few ideas. The sled will probably take a a few hours to put together once I figure out how to do it. Then I can WHIP out the pieces and it will make FUTURE projects go much more quickly (and I have plenty in mind).